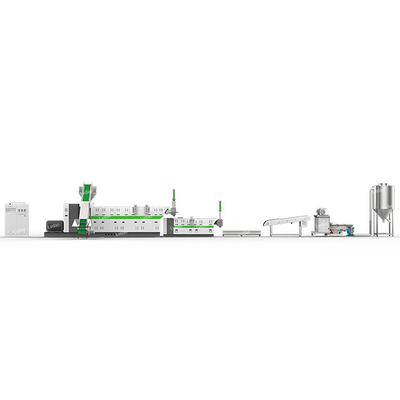

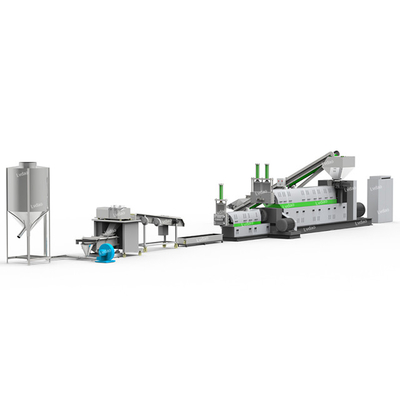

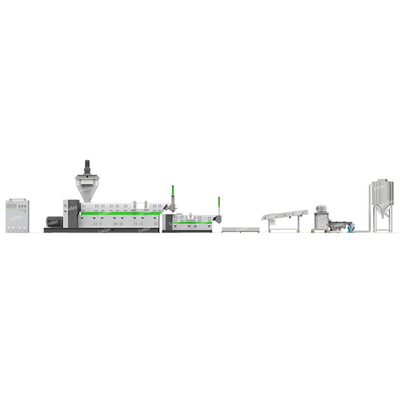

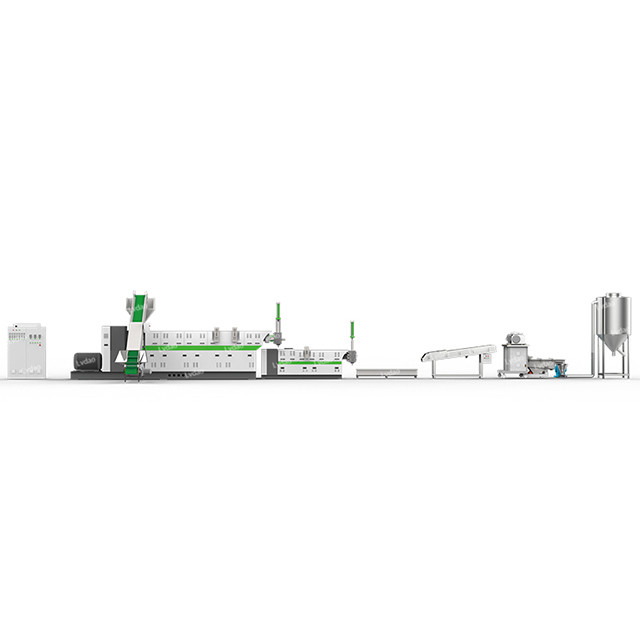

250KG/H PP PE Plastic Granules Making Machine Automatic Output Double Stages

Product Details:

| Place of Origin: | China |

| Brand Name: | Lvdao |

| Certification: | CE, IAF, SGS, ISO9001:2008 |

| Model Number: | LDD-SJP-120-110 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 set |

|---|---|

| Packaging Details: | film packaging |

| Delivery Time: | 40 work days upon confirmation of purchasing order and down payments arrival |

| Payment Terms: | T/T, L/C |

| Supply Ability: | 30set/month |

|

Detail Information |

|||

| Condition: | New | Type: | Granulating Recycling Machine |

|---|---|---|---|

| Capacity: | 200-250kg/h (depend On Material) | Place Of Origin: | Zhejiang, China(Mainland) |

| Brand Name: | Lvdao | Recycle Materials: | PP, PE Hard Scrap |

| Screw Design: | Single Screw | Voltage: | Customized (220v/240v/415v/440v, 50hz/60hz) |

| Motor Power: | 45kw,15kw | Dimension: | APPROX. 10*3*2.5m(L*W*H) |

| Weight: | APPROX. 6000KG/SET | Certification: | CE, SGS, ISO9001:2008 |

| Warranty: | 1 Year | After-sales Service: | Engineer Oversea |

| Usage: | Making PP PE Plastic Pellets | Final Products: | PP, PE Granules(reuse Or Resale) |

| Colour: | Customized | Stage Type: | Double Stages |

| Screw Diameter: | 120*170*3400 | Advantage: | Long Service Time |

| Motor: | Wannan Motor,Siemens | ||

| Highlight: | plastic extrusion machine,plastic granules making machine |

||

Product Description

Plastic PP PE Granulator Machine is designed for the pellet and re-pellet production obtained from plastic, Especially forcused on PP PE ranulation.

The granules that the LVDAO particle cutting machine produce are uniform and beautiful.

Advantages:

1) noodle water-cooling cutting , ensures good shape.

2) having 2 filtrations. ensuring the purity of final pellets

3) Extrude more evenly, having more stable output and better pellets

4) CE, IAF, SGS, IOS9001:2008 Certificate

5) Long service life

6) Customized

7) Engineers available overseas

Parameter table:

| Model | Screw dia.(mm) | Long dia.ratio(mm) | Output(kg/h) | Power(kw) | Screw rotate speed(r/min) |

| LDD-SJP-80-65 | 80-65 | 28:1-10:1 | 70-100 | 18.5-22 | 73 |

| LDD-SJP-90-85 | 90-85 | 28:1-10:1 | 90-120 | 22-30 | 73 |

| LDD-SJP-100-90 | 100-90 | 28:1-10:1 | 120-150 | 30 | 73 |

| LDD-SJP-110-100 | 110-100 | 28:1-10:1 | 150-180 | 30-37 | 73 |

| LDD-SJP-120-110 | 120-110 | 28:1-10:1 | 200-250 | 45 | 73 |

| LDD-SJP-130-120 | 130-120 | 28:1-10:1 | 250-300 | 45-55 | 73 |

| LDD-SJP-140-130 | 140-130 | 28:1-10:1 | 350-400 | 55-75 | 73 |

| LDD-SJP-150-140 | 150-140 | 28:1-10:1 | 400-450 | 75-90 | 73 |

Specifications

| Feeding | Hand feeding/ feeding machine system |

| Extruder | Single screw, Two stage extrusion |

| Cutting Type | Strand (noodle) type pelletizing |

| Cooling Type | Water cooling |

| Product | Plastic pellets/granules |

| Material Type | PP Non-Woven Fabric cloth |

| Machine Components | Cabinet,extruder,water cooling tank,blower,cutter,silo |

| Output range | 70kg~ 450 kg/h |

| Screw Diameter | 80~160mm (customized) |

| Screw L/D | 28:1 (customized) |

| Screw Material | 38CrMoAL |

| Voltage | Customized based on request (For example: USA 480V 60Hz, Mexico 440V/220V 60Hz, Saudi Arabia 380V 60Hz, Nigeria 415V 50Hz...) |

| Delivery Time | 40days for customized machine. |

| Warranty | 1 year |

| Technical Assistance | Engineers available to service machinery overseas |

OUR FACTORY

Ever since the beginning in 1992, Lvhua Plastic & Rubber Machinery Industrial Trade Co., Ltd has been satisfying its customers with its exceptional services and products. Our desire to achieve excellence has made us what we are today, and has allowed us to evolve. Contact us today for more information about our products and services.

FAQ

Q:Are you machinery factory or trading company?

A:We are machinery factory with 20 years experience in Ningbo. And we can export machines by ourselves.

Q: Which kind of machine do you make?

A: We mainly produce plastic recycling machine,pelletizing machine and other auxiliary machine , according to the different raw material, different output and different industrial voltage in working place,you can choose different machines.

Q: How can we visit your company and machines?

A: Our factory is located in Ningbo City,near Shanghai and Hangzhou. About 3 hours away from Shanghai International Airport.

Q:Can you customized machine?

We can make the products following the customers' requirement,like the shape,size,color,logo and other spec details.