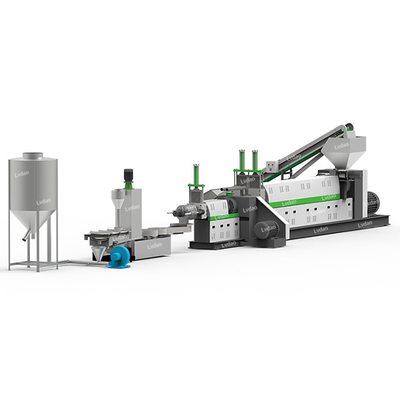

Hard Scrap Waste Recycling Machine Plastic Recycling Plant Machinery ISO9001

Product Details:

| Place of Origin: | China |

| Brand Name: | Lvdao |

| Certification: | CE, IAF, SGS, ISO9001:2008 |

| Model Number: | LDK-SJP-150-150 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 set |

|---|---|

| Packaging Details: | film packaging |

| Delivery Time: | 30-40 work days |

| Payment Terms: | T/T |

| Supply Ability: | 300 sets/ per year |

|

Detail Information |

|||

| Condition: | New | Type: | Pelletizer Machine Line |

|---|---|---|---|

| Capacity: | 300-400kg/h | Band Name: | Lvdao |

| Material: | HDPE, LDPE | Voltage: | Customized |

| Motor Power: | 132kw(main Motor) | Dimension: | APPROX. 15*3*2.5(L*W*H) |

| Weight: | APPROX. 7000kg | Certification: | CE, IAF, SGS, ISO9001:2008 |

| Warranty: | 1 Year | After-sales Service: | Engineer Oversea |

| Usage: | Plastic Pelletizing | Final Product: | HDPE, LDPE Pellets |

| Motor Band: | WN | Colour: | Customer Depend |

| Stage Type: | Two Stage | Screw Size: | 150*170*4400mm |

| Advantage: | Long Service Time | Automatic Grade: | Semi-Automatic |

| Highlight: | plastic recycling machine,plastic waste recycling machine |

||

Product Description

Customized Waster HDPE LDPE Plastic Pelletizer Machine Line 120 * 170 * 3300mm

Our machine function is pelleting recycling plasitc. Sorting and grouping plastic materials according to resin type is an important first step in the recycling process because contamination can render a batch of material un-reusable. The most frequently recycled resins, Polyamide (Nylon, PA), must be carefully separated from one another in order to enable further processing. Contaminants within each type of plastic must also be removed from the base resin to ensure stock purity.

Plastic Pelletizer Machine is designed for the pellet and re-pellet production obtained from plastic, especially forcused on HDPE LDPE.

The granules that the LVDAO particle cutting machine produce are uniform and beautiful.

Advantages:

1) noodle water-cooling cutting , ensures good shape.

2) fhaving 2 filtrations. ensuring the purity of final pellets

3) Extrude more evenly, having more stable output and better pellets

4) CE, IAF, SGS, IOS9001:2008 Certificate

5) Long service life

6) Customized

7) Engineers available overseas

Specifications

| Feeding |

Hand feeding/ feeding machine system |

| Extruder | Single screw, Two stage extrusion |

| Cutting Type | Waterring cut type pelletizing |

| Cooling Type | Water cooling |

|

Product |

Plastic pellets/granules |

|

Material Type |

HDPE LDPE scrap |

|

Machine Components |

Cabinet,extruder,water cooling tank,blower,cutter,silo |

| Output range | 100kg~ 450 kg/h |

| Screw Diameter | 80~150mm (customized) |

| Screw L/D |

28:1 (customized) |

| Screw Material | 38CrMoAL |

| Voltage | Customized based on request (For example: USA 480V 60Hz, Mexico 440V/220V 60Hz, Saudi Arabia 380V 60Hz, Nigeria 415V 50Hz...) |

| Delivery Time | 50days for customized machine. |

| Warranty | 1 year |

| Technical Assistance | Engineers available to service machinery overseas |

![]()

Pelletizing reclaimed plastic is the final step in most recycling processes. Converting post-consumer plastic into pellets allows for easier distribution and remanufacturing, and ultimately benefits the speed and effectiveness of reintroducing recycled plastic into industrial manufacturing. After sorting, drawing, separating, and drying the reclaimed material, the flake stock is ready to be extruded into pellets.

Plastic recycling pelletizer series depends on plastic itself, which plastic are you recycling , different plastics have different application.If your want know more, feel free to contact US