High Feeding Plastic Recycling Machine LDS Dry Film Granulating Extruder

Product Details:

| Place of Origin: | Ningbo, China |

| Brand Name: | LVDAO |

| Certification: | ISO9001,CE |

| Model Number: | LDS-150-140 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 SET |

|---|---|

| Price: | Negotiable |

| Packaging Details: | Customer-made |

| Delivery Time: | Received the advanced money 40 days |

| Supply Ability: | 10 sets per month |

|

Detail Information |

|||

| Product Name: | Plastic Recycling Machine | Feature: | High Feeding |

|---|---|---|---|

| Materials: | Dry Film ,PP,PE | Motor(kw): | 90KW |

| Material: | Dry Met | Extruder Design: | Double Stage |

| Color: | As Request | ||

| Highlight: | plastic recycling machine,plastic waste recycling machine |

||

Product Description

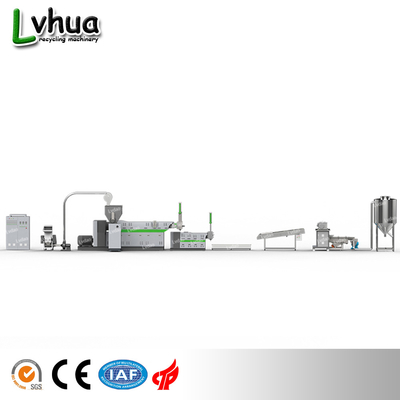

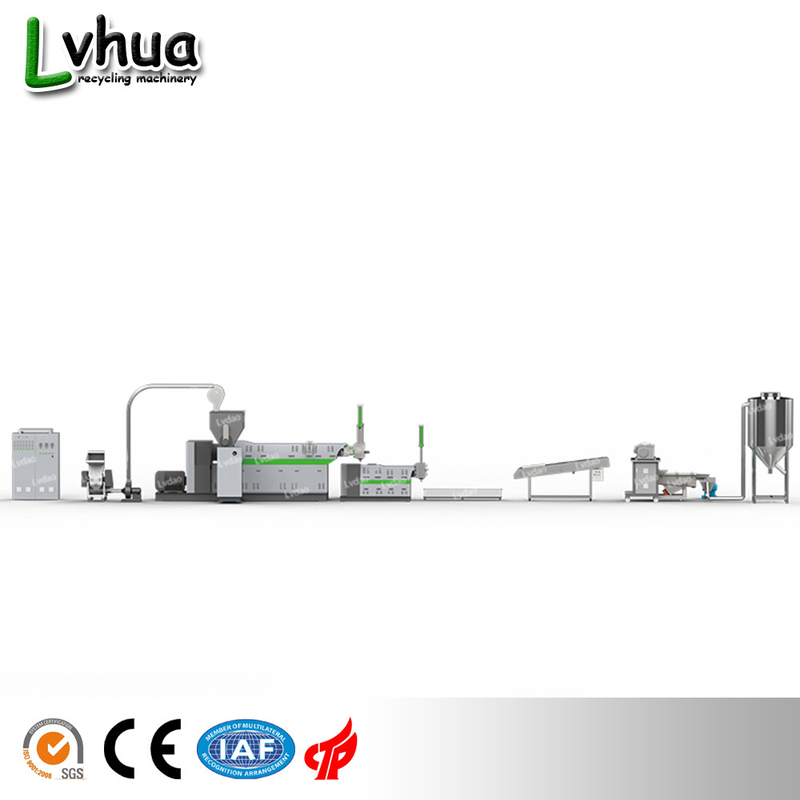

High quality plastic recycling machine,LDS Dry film Granulating extruder

Production descriptions:

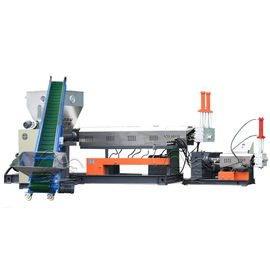

This extruder granulating line adopt special side feeder and the screw temperature control system will ensure the material plasticization; The pelletizer is well blanced to match the extrusion die face.

The capacity is from 300kg/h-400kg/h.Side feed can avoid the blocking caused by force feeder,especially for high capacity machine.It can improve the capacity when solve the feeding problem.

It is suitable for both soft film and hard scrap,dry material and wet material.

2) You can choose crusher with blower or conveyor to feeder the material according to your demand.

3) Side feed can avoid the blocking caused by force feeder,especially for high capacity machine.

4) You can choose water tank or hot cutting system.

The process flow of this line as blow: Dry flim flakes--- mixing---material feeder--- single screw extruder of Main extruder--- screen changer --- single screw extruder of Baby extruder --- hydraulic single screen changer ---Water cooling tank and Laying plate ---Air blower--- Pelletizer --- Packing silo with conveying blower

Specifications:

| Model | Motor(kw) | Weight(kg) | Size(L*W*D) |

| LDS-120-115 | 45 | 300 | 1500*1500*2000 |

| LDS-130-120 | 55 | 600 | 1700*1700*2100 |

| LDS-140-130 | 75 | 1000 | 1800*1800*2200 |

| LDS-150-140 | 90 | 1300 | 1800*1800*2200 |

Detail images:

![]()

![]()

Packaging & Delivery:

1. We can provide custom-made packaging.

2. Prompt deliver at the very day.

3. Well-trained and disciplined packing team.

4. After-sale service: Any questions or problems after receiving the product, please feel free to contact us. Problems would be solved for you immediately.

5. Sophisticated and professional logistic agent..

Competitive advantages:

The series of units have the following characteristics.

1. We provide you with a complete plastic recycling base extrusion granulator, saving you the extra effort when you purchase other auxiliary equipment.

2. The use of the side feeding device and the improvement of the precision of each transmission part make the production more energy saving and efficient.

3. The proportion of main components has been fully demonstrated to be reasonable, which brings you a more secure use.

4. The hydraulic system is applied in the work of changing the network, making the operation more convenient.

5. The standard electrical control system makes the production more safe and efficient, and improves the double safety performance of people and equipment.

6. The heating system is fully enclosed, which can better save heat and minimize the occurrence of burns.

7. The granules produced by this series of units are more even and full, more suitable for the needs of the market, and recognized by the majority of customers.

Company profile:

Yuyao lvdao plastic and rubber machinery Co.,Ltd.(lvdao plastic machinery) is a professional manufacture of plastic Recycling machine and pelletizing extrueder,and it has been in the plastic Recycling field for almost two decades.

Our branch Office put into operation in August 2011.The site covers an area of twenty thousand square meters.We have modern technology center and all kinds of processing equipment with testing facilities. Our company always take customer satisfaction as purpose,customers constantly support and identity. Always continue expanding our market and promoting our technology progess.

Our equipment have already had many invention patents now. Passed ISO9001:2008 certification. The plastic pelletizing unit has passed the CE authentiction security. In 2007 our LDA series are on national torch plan projects. In2008 Our company was awarded the ningbo high-tech enterprises.And the company take the national innovation fund projects in 2009.